Selective Electroplating

Duke Bletsch Lab

Motivation

Electroplating, the process of coating one metal with another using electricity, is usually used to make uniform protective layers—but I wanted to see if it could instead be used to 'print' images onto metal.

Background

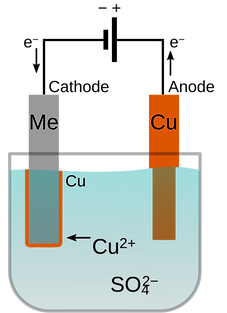

Electroplating is the process of coating a conductive surface with a thin layer of metal by running an electric current through a solution of dissolved metal ions. This allows precise, micron-level control of coatings used for corrosion resistance, conductivity, or aesthetics, with common metals including nickel, copper, and zinc.

Electroplating

Setup

The system was built on a 3018 benchtop CNC router, with a plastic basin of electrolyte on the bed and the cathode workpiece fixed inside. A custom 3D-printed nozzle holding the anode replaced the spindle, both electrodes were wired to a constant-current power supply, and the CNC was controlled via Candle G-code software.

Calibration

A custom Python script was created to convert images into G-code, using grayscale pixel brightness to control nozzle dwell time and plating thickness. Because plating results vary by metal, electrolyte, and electrical parameters, a gamma correction function was implemented and calibrated through test gradients. Image-processing analysis was used to tune parameters.

How long each pixel plates, for all brightness values and select gamma values

Normalized brightness heatmap of previous image for select gamma values

Theoretically perfect gradient lines (0-255 evenly spaced) printed with different gamma values. Attempt to isolate linear gradient regions.

Graphical representation of heatmap, functions appear sigmoid

Isolated linear region of sigmoid function. Used to determine algorithm for plating directions

Results

Albert Einstein

Mona Lisa

Empire State Building

Duke Chapel

Duke Chapel

Blue Devil Costume

Poster